Fujitsu Digital Manufacturing FJGP4D

Overview

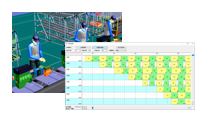

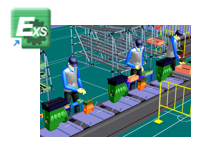

FJGP4D creates 3D models of production lines and simulates the production process. By placing the parts of the assembly target product and workers, and inputting assembly procedure information, simulation can be easily performed. Simulation results can be evaluated by reviewing process balance charts, work combination charts, and quantitative data such as walking distances, making it easy to identify bottleneck processes.

Simulation data is updated instantly upon changes to production equipment and part placement, as well as work procedures. Multiple production line plans can be created and compared in a short time, allowing for the rational determination of the optimal plan.

The benefits of virtual production line verification

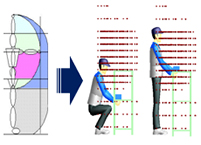

Using only 2D drawings for production process planning often leads to overlooked issues, resulting in significant time and cost overruns for rework after production line construction.

Many of the issues arise from consideration of only 2D, such as lack of consideration of the height direction and lack of communication between departments.

Utilizing FJGP4D for virtual production line verification allows for high-precision validation before actual construction by building the layout with actual positional relationships and defining work instructions sequentially within a virtual space.

Examples of achieved effects:

- Cell production productivity increased by 40%

- Operation of assembly part picking reduced by 60%

- Mass production preparation period reduced by 40% compared to conventional methods

Featurs

Clicking an item will display details of each feature.

FJGP4D is a trademark of FUJITSU LIMITED.

All other product names are trademarks or registered trademarks of their respective owners.