DIPRO VridgeRDigital Manufacturing Tool

Interpreting Manufacturing Information with the Data Thread Viewer

Issues in cost estimation

"It is difficult to conduct an initial review in a short period of time and to accurately estimate costs."

"Mold modifications frequently occur due to omissions in production requirements."

Benefit

Improve the quality of estimates and shorten the review period

A viewer that only displays geometry or PMI (Product Manufacturing Information: annotations) cannot read "Manufacturing information".

VridgeR interprets the shape characteristics and industry standard PMI required from a manufacturing perspective and visualizes them in the form required by engineers.

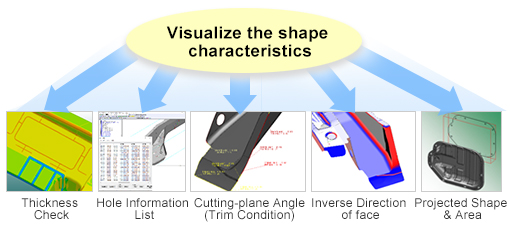

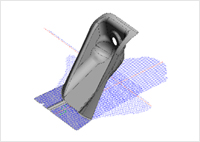

Visualization of shape features that engineers want to know

VridgeR can visualize shape characteristics that are important for manufacturing based on engineering knowledge. According to this, data is able to be utilized for the review of press working, plastic molding and so on. Moreover, even young and overseas engineers will carry out their work process with preserving quality and term equivalent to experts.

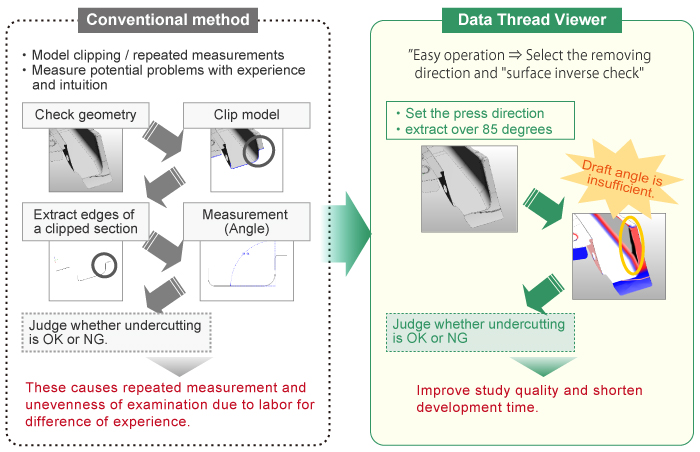

Changing Estimation Work with the Data Thread Viewer: An Example Undercut Study

Challenges with 3D Drawings

"The 3D data from the supplier is not displayed accurately, and the product cannot be made."

Converted many 3D drawings

VridgeR has more than 10 years of experience as a 3D drawing viewer and has supported the use of 3D drawings in manufacturing.

Read major CAD data completely (Based on JAMA standards)

VridgeR can accurately display and convey major CAD shapes,as well as design instruction and attribute information,

and even CAD system-dependent information.

VridgeR is also quick to comply with JAMA's industry standards.

*JAMA: Japan Automobile Manufacturers Association

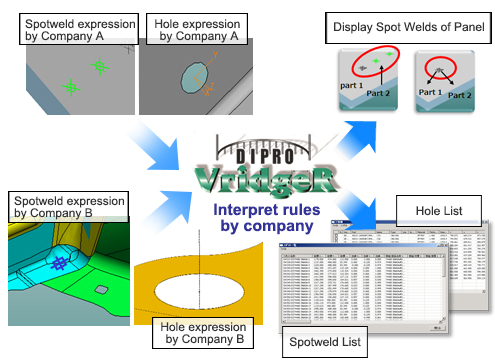

VridgeR also interprets per-company 3D drawing rules.

Data distributed in practice depends not only on industry standards but also on company rules.

VridgeR accurately conveys information that is required for operations that cannot be covered by industry standards. If this level of information cannot be distributed, it is not effective in practice.

Voice of the Customer

Automotive parts supplier

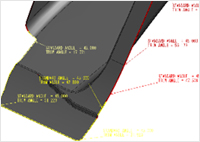

(trim condition)

Conventionally, a trim condition check performed at the time of checking the structure of a press die requires considerable man-hours and experience.

The data threading function of VridgeR enables automatic detection of potential problem areas, which not only reduces the number of verification steps, but also significantly improves the accuracy of estimation by eliminating the oversight of problem areas.

Automotive parts supplier

By the Projected area function, the logistics cost was calculated by 100 minutes (1 part approximately 5 minutes) for 20 parts when it was estimated by hand calculation in the past, but it can be completed in 20 minutes because of the function that can be easily calculated in one operation.

Since it is possible to estimate the logistics cost in about one minute for each part, the time is drastically reduced.

Automotive parts supplier

Conventionally, the cost calculation of the member was carried out by making the cross section in many places manually, but the extended shape can be automatically made by the Data Thread function, and the length of the longest side can be easily known, and the examination man-hour can be remarkably reduced.

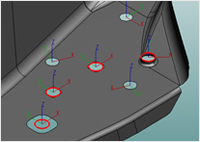

Automotive parts supplier

There was no function to check if the flat area exists around the hole, so CAD was used. VridgeR has that feature, which is very helpful.

The image data shown are provided by Nissan Motor Co., Ltd. and the Japan Automobile Manufacturers Association.

DIPRO VridgeR is a trademark of DIGITAL PROCESS LTD.

All other product names are trademarks or registered trademarks of their respective owners.