DIPRO Xphere (DIPRO krɔ':sfíər) Virtual Reality for Manufacturing

Key features

Basic function

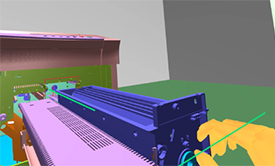

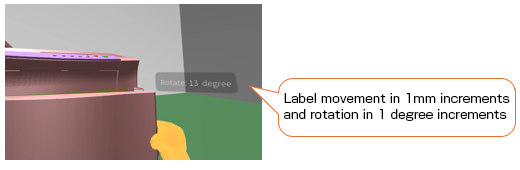

Move parts, interference / contact check

- Parts can be mounted and removed by gripping and moving parts in VR space. You can move things along an axis as well as in any direction, so for example you can pull the unit straight out or push the trolley along the floor.

You can also define assembly units to move parts as assembly parts.

* You can set the assembly unit in the desktop application displayed in the VR space. - The controller vibrates to notify you of any interference between the moving part and its peripheral parts. It is also possible to stop a part in place when a moving part interferes.

Mount/remove parts

Move along floor

Interference is notified by controller vibration

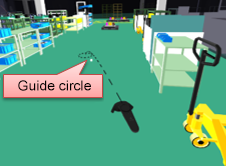

Moving horizontally and vertically in VR space

- Changes the standing position in VR space. It can be moved instantaneously to the place where you want to see a large plant or a large-scale facility, and can be moved in the direction of height, so it is possible to study the worlability at hight places and in different height from the self.

Move to the position

specified by the guide circle

Adjusts height and foot height according to a specified value

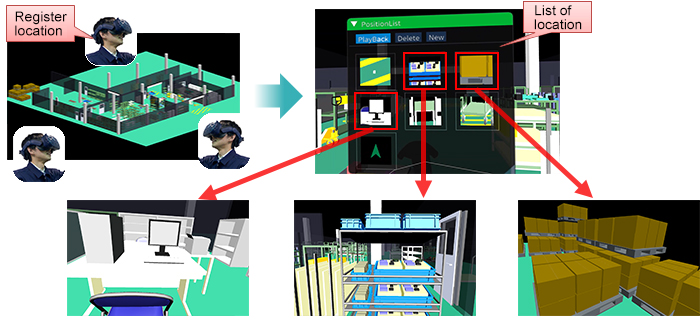

Registering locations in VR Space

- Any location can be registered. The registered locations are listed, and you can move to them by selecting them.

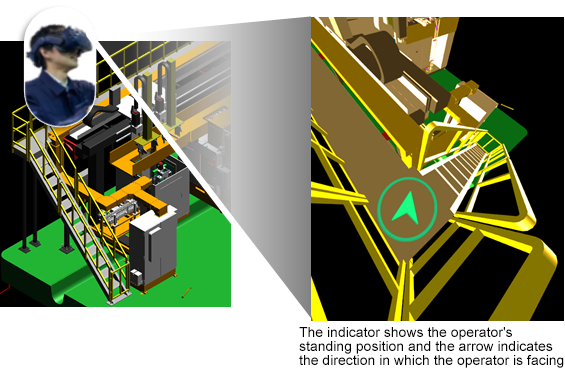

Display the standing position

- Displays the standing position in VR space. You can grasp your position by displaying a standing position mark at your feet.

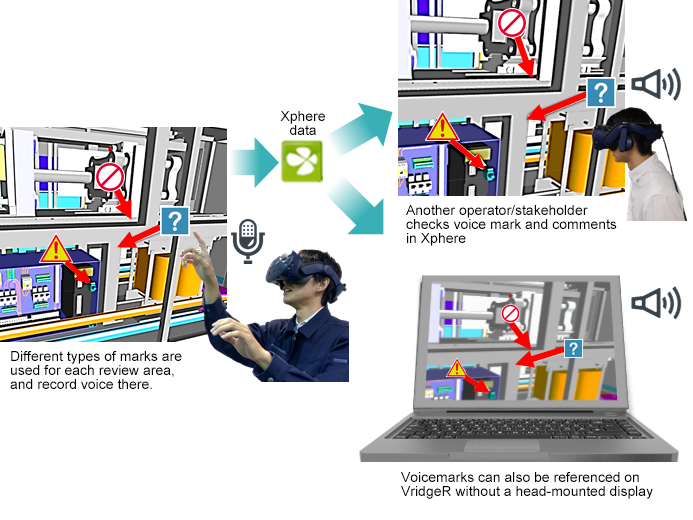

Voice mark function

- You can now mark the points you've pointed out during VR verification and record the comments of people who have experienced VR by voice. Also, it is easier to understand the pointed out items by using different mark images.

- By passing in the data, other workers and people in other departments can see what was pointed out later in the VR space.

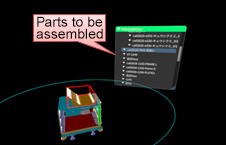

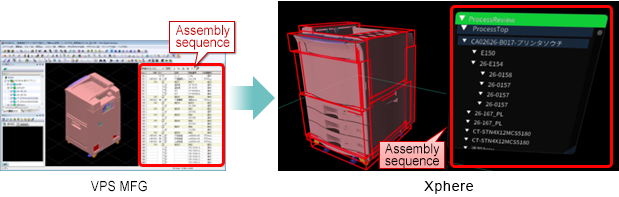

Confirming the assembly sequence

- You can check the assembly sequence in VR space by importing the assembly sequence into Xphere. Assembly sequence and part display status are linked, and the part assembly position can be confirmed in real scale. Enables review of assembly order from the operator's perspective.

Flow View of Assembly Sequence

Measurement of dimensions and distance

- Measures the distance between two points. Select the start and end points in VR space.

Measures the distance between two points

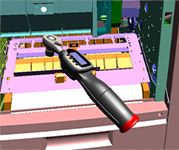

User registered tool

- Displays the user's pre-registered geometry as a tool. It can verify whether or not the tool is inserted.

- The hand can be displayed in VR space by registering the hand shape in the user tool. You can check the size and movement of your hands and also check the interference between your hands and peripheral parts.

Display tool

Display hand

Display of part attributes

Display the attribute information that has been set in the imported data of the selected part.

For example, In case you set the material name, part number and weight of a part, you can check the weight of a part in the VR space and use it as a reference for assembly work.

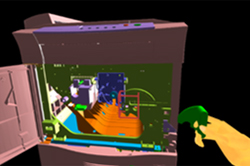

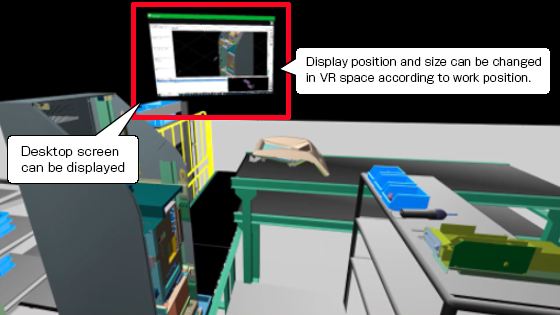

Share Desktop Screen

- In the VR space, it is possible to view and interact with the desktop screen.

- While displaying work orders such as "PDF" and "Excel" and animations such as "VPS MFG", you can confirm the assembly in VR space before the actual equipment is implemented.

Additionally, by viewing a meeting, such as Teams, you can join the meeting while validating it in VR space.

Projection of VR space viewed by VR operator

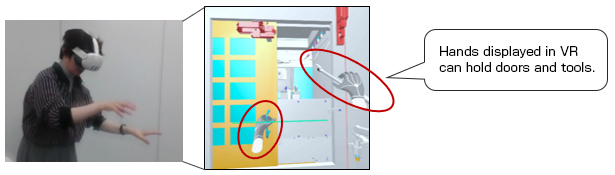

Hand capture

- You can express your finger movements in VR space, and you can also grip parts.

- It is possible to check the movement of the hand and the operation feeling of the fingertip in a narrow place, such as whether the finger can reach the switch or the parts can be pinched and inserted.

- *

- When using the Hand Capture function, you cannot operate the controller.

Grasping the parts with the hand capture function

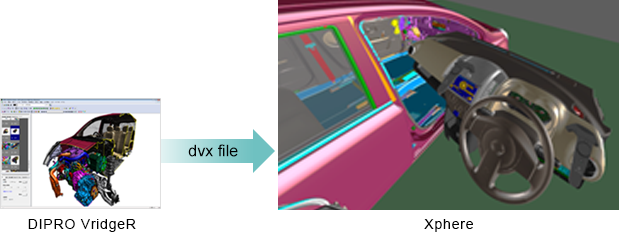

Importing Point Cloud Data

- You can import point cloud data, such as from a scanner, into Xphere via VridgeR*.

- When new equipment is installed in an existing factory, it is possible to check the positional relationship with peripheral equipment.

- *

- Read about VridgeR at the link below.

DIPRO VridgeR V4.11

3D model overlaid on point cloud data

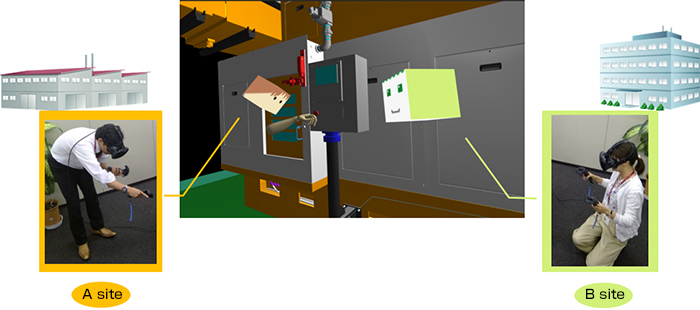

Remote location/multi-person review

When CAD data is created, people from different locations gather in a single VR space and verify it.

This will shorten the time required, accelerate the creation of quality, and improve productivity.

Space Sharing

We provide a space where people gather and discuss in a VR space.

You can check the others's position and orientation with the avatar.

Each participant can point out the points freely.

You can move the parts freely and show them to the others.

Connecting to other DIPRO software

Import simulation data

By reproducing the movements of machines, devices and people set up by other DIPRO software in VR space, Xphere can simultaneously verify the movements and workability of machines, devices and people from the early stage of the development process.

In addition, the assembly animation can be reproduced in the VR space and the assembly procedure can be

confirmed from the operator's point of view.

Collaboration with the VPS IOC

- In the VR space of Xphere, it is possible to reproduce the movement of mechanism set by VPS IOC.

- FJVPS IOC (V20L20R01 or later) are required for VPS IOC operation coordination.

- *

- FJVPS IOC is software sold only in Japan.

in the VPS IOC

a worker's point of view with Xphere.

FJGP4D operation coordination

The factory (Product assembly procedures, human movement) created by VPS GP4 is reproduced, and verification can be performed by entering the workplace.

(Perform Product Procedure)

Reproduced on Xphere

FJVPS MFG operation coordinate

The assembly animation created by VPS MFG can be reproduced in real scale, and the assembly procedure can be checked from the worker's viewpoint.

from a worker's point of view in Xphere

- The part movement (joint information) defined by “VPS MFG” can be import and viewed in Xphere VR space.

It can be used to reproduce the movement of doors, slides, etc. close to the real thing in VR space, to confirm product assembly, and to check workability by examining the opening and closing of doors.

Import data

By directly importing data from other DIPRO software such as VridgeR, VPS, etc., it is possible to reproduce not only the shape, assembly configuration, and attributes, but also the results examined in each software such as the assembly process in VR space, enabling the review in real scale.

We are planning to add more collaborations with our products in the future.

Import VPS MFG data

- It is possible to import VPS MFG data and check the shape and assembly sequence in the VR space of Xphere.

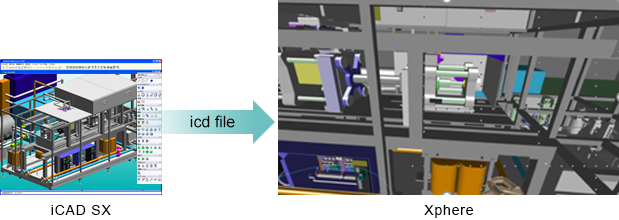

Import iCAD SX data

- It is possible to import iCAD SX data and confirm each model shape, color, and material color in Xphere VR space.

Import DIPRO VridgeR data

- It is possible to import VridgeR data and confirm model shape, assembly sequense, and animation in Xphere VR space.

Supports various types of CAD data format

- Various 3D data including CAD can be directly converted and brought into a VR space.

In addition, design intent such as configuration information and attributes can be captured, enabling a variety of timely reviews. - CATIA V5, JT, Parasolid and VRML import capabilities are provided.

*Other CAD data formats will also be supported.

Supported device

Meta wireless VR goggles

- Meta Quest2, Meta Quest Pro, and Meta Quest3 are available.

It is readily to verify in VR space by wireless and sensorless.

Meta Quest3

VIVE (VR Kit) by HTC Corporation

- HTC VIVE Pro, HTC VIVE Pro Eye, HTC VIVE Pro2 are available.

It's a high-resolution display that allows for more realistic VR verification.

HMD Controller

Valve INDEX (VR Kit) by Valve Corporation

- Support for VALVE INDEX VR kit (Up to 144 FPS HMD, wearable controller). You can perform operations such as gripping and releasing parts without feeling like you are holding the controller.

the VALVE INDEX controller

- *

- The image data shown are provided by Nissan Motor Co., Ltd. And iCAD LTD.

DIPRO Xphere and VridgeR are a trademark of DIGITAL PROCESS LTD.

All other product names are trademarks or registered trademarks of their respective owners.